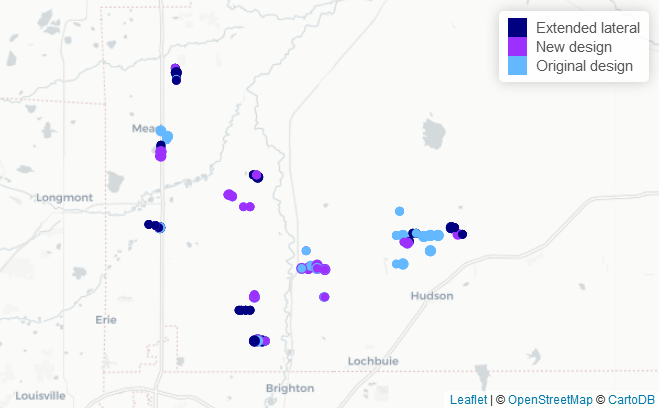

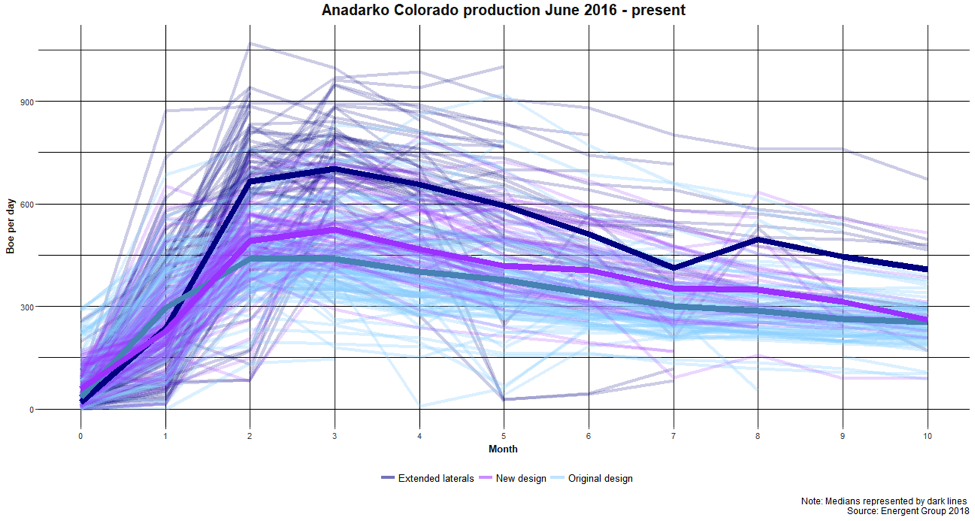

The operator stated in its first-quarter 2017 operations report that a new completion design is being tested in their Colorado acreage. The new design involves increased fluid volumes coupled with tighter stage spacing. The report also states early results of the new design show improvements of more than 10% cumulative oil to date, with their fourth-quarter 2017 operations report estimating a 20% uplift in EURs.

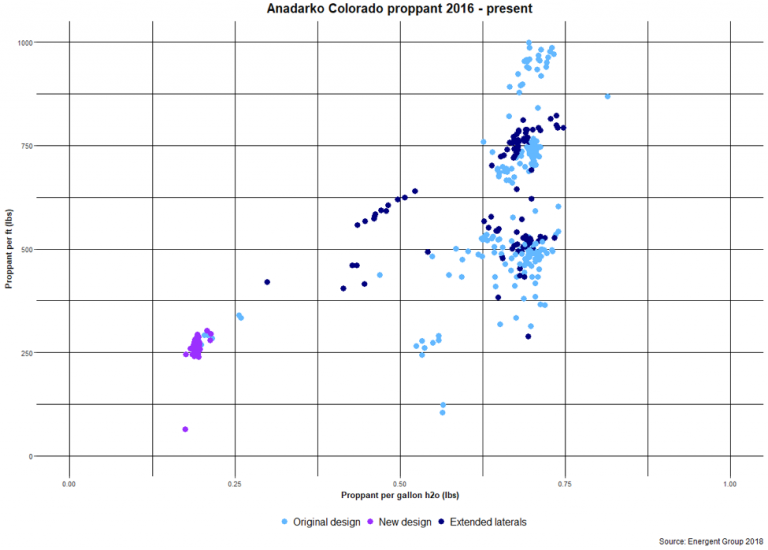

One crucial part of the puzzle, proppant amount, is not mentioned in the reports. Energent took a closer look and found some intriguing information. Using median monthly production and comparing wells of similar lateral lengths, Energent confirms the new design shows a 10% increase in 6-month cumulative BOE, all with half the amount of proppant. Anadarko’s original well design uses between 500 and 800 pounds of proppant per foot with a proppant per gallon water ratio above 0.50. The new well design averages near 250 pounds per foot and has a proppant per gallon water ratio below 0.25.

One crucial part of the puzzle, proppant amount, is not mentioned in the reports. Energent took a closer look and found some intriguing information. Using median monthly production and comparing wells of similar lateral lengths, Energent confirms the new design shows a 10% increase in 6-month cumulative BOE, all with half the amount of proppant. Anadarko’s original well design uses between 500 and 800 pounds of proppant per foot with a proppant per gallon water ratio above 0.50. The new well design averages near 250 pounds per foot and has a proppant per gallon water ratio below 0.25.

Although Anadarko’s extended lateral well design (lateral lengths greater than 7,500 ft) still show higher cumulative production volumes, the cost savings of the new design is likely to translate to higher NPV when full cycle costs are taken into account.

Although Anadarko’s extended lateral well design (lateral lengths greater than 7,500 ft) still show higher cumulative production volumes, the cost savings of the new design is likely to translate to higher NPV when full cycle costs are taken into account.

With sand prices on the rise (one Permian sand mine reported a 38% price increase in 2017), a new well design that uses significantly less proppant could be a game changer in the world of unconventional oil and gas. Will the results be long lasting, and can they transfer across operators and basins? Time will tell. Stay tuned to Energent for detailed updates.

With sand prices on the rise (one Permian sand mine reported a 38% price increase in 2017), a new well design that uses significantly less proppant could be a game changer in the world of unconventional oil and gas. Will the results be long lasting, and can they transfer across operators and basins? Time will tell. Stay tuned to Energent for detailed updates.